Çalışma dinamiğimiz içinde bir ara durup geriye baktığımızda gördük ki grup olarak yarım asırlık uzun bir geçmişi ardımızda bırakmışız.

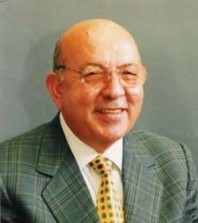

Bugün çağımızın gerektirdiği rekabet ortamında, sayısız şirket ve ihracatçı arasında üst sıralarda yer almamızın haklı gururunu paylaşma zamanının geldiğini düşünüyoruz. Zirveye doğru attığımız adımlar ve başarılar, geçen yarım asır boyunca çok yol kat ettiğimizin en belirgin göstergesi… Kurucumuz Sayın Rıfat KALEOĞLU ile birlikte , faaliyet alanlarımızın kısıtlı olduğu günlerde, cesaretimiz, vizyoner bakışımız, taşları hedeflediğimiz doğru karelere koymamız önümüzü açtı. Sağlam bir yol haritası çizerek, işin en zor kısmını aşmış olduk. Kurucumuz Sayın Rıfat KALEOĞLU’nun temellerini attığı çalışma ilkelerimiz ve haritamız bizi, kalıcı değerler bırakma yolunda yönlendirdi.